Time-Tested, Accurate & Dependable Solutions

Welcome Advanced Process Technology Inc. and new customers alike. Please browse our site to learn about how we can best serve you and your process needs. Whether its specialty blended tungsten powder filled epoxy, a standard urethane or even MOCA based formulation, we have the technology and knowledge to accomplish your processing needs with ease.

Innovators and Leaders

What do Titleist golf balls, NASA solid rocket boosters and Boeing’s next-gen aircraft components have in common? They all require the precision and reliability that is delivered by DeSantis Mechatronics’ open casting and closed-mold material processing machines.

When the world’s largest manufacturers have a cast urethane or epoxy composite production challenge, they commonly turn to our renowned engineering and manufacturing specialists for a solution. Since 1969, we have quietly solved thousands of real-world production challenges and invite the opportunity to share our knowledge and processing equipment with you. From simple process tanks to complete multiple-component processing systems, your application’s solution is here at DeSantis Mechatronics.

Choose a Process

Open Casting

Dispense air-free metered and mixed epoxy and cast polyurethane formulations into open-top molds.

Closed-Mold Injection

Dispense air-bubble-free metered and mixed resin formulations into closed molds with positive pressure from the top or bottom.

Vacuum Casting

The vacuum casting process draws vacuum on the assembled mold before the air-free metered and mixed material is dispensed into the air-free mold.

Resin Transfer Molding

The RTM process injects metered and mixed, air-free epoxy resin at low to relatively high injection pressures into closed molds containing high fiber content preforms.

Vacuum-Assisted Resin Transfer Molding

The VARTM infusion process draws vacuum on the VARTM mold and its assembled preforms before the air-free, on-ratio, metered and mixed epoxy is infused at low pressure into the air-free VARTM mold.

Filament Winding - Bath Filling

Wet filament winding is an automatic process that runs composite fibers down into and then out of a bath or reservoir filled with epoxy. The epoxy-wetted fibers are then wound on a rotating mandrel.

Our Products

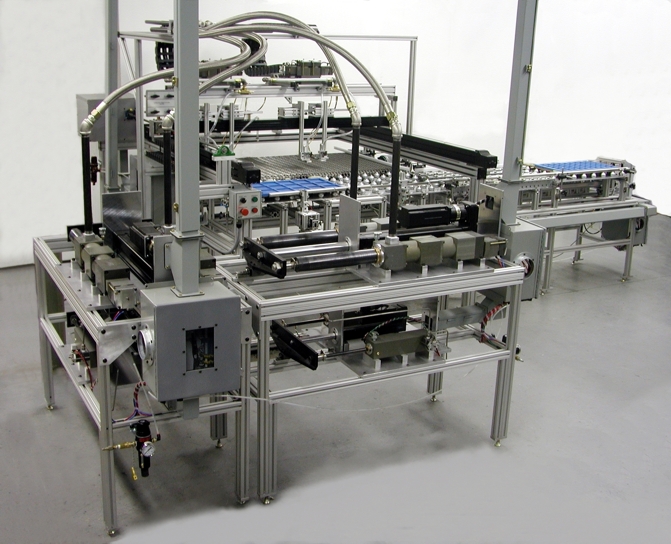

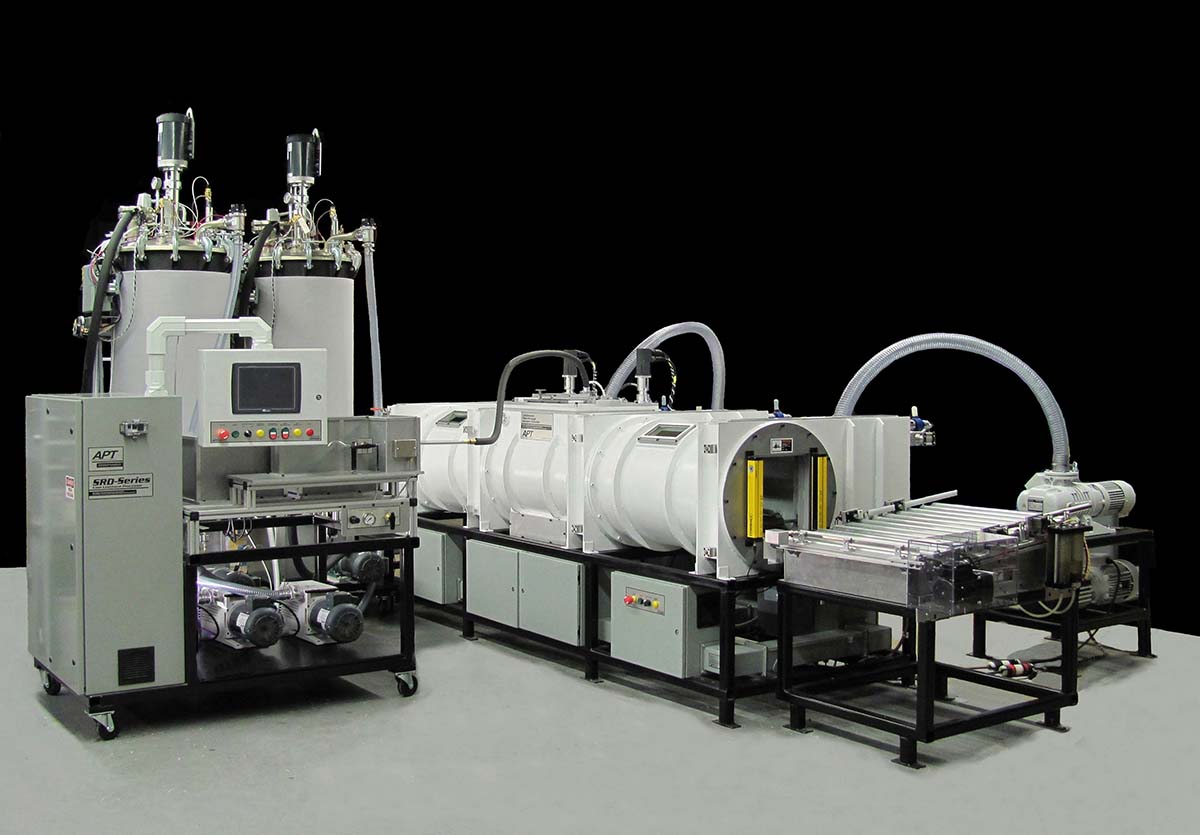

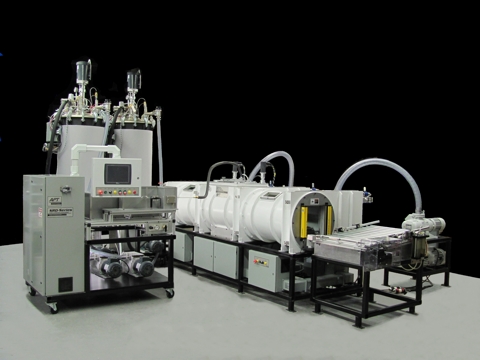

SRD/SRD i Series

Digitally accurate and fully programmable, SRD-Series systems utilize state-of-the-art PLCs and servomotor-control for the rotary gear metering pumps.

ECS Series

These systems are specifically designed to degas, meter, mix and dispense abrasive-filled and unfilled, multiple-component resin formulations.

Flying Wedge (HT)

Accurate and repeatable system performance with no unnecessary sophistication make the HT-Series shot dispensing systems both affordable and dependable.

Tanks

These tanks are used for mixing, heating and degassing batches of resin. They are also available without heat.

RTM and VARTM

Dispense void-free, accurately metered and mixed epoxies and polyesters into RTM and VARTM molds for superior preform penetration and void-free resin injected parts.

Vacuum Casting Systems

Dispenses air-free, accurately metered, mixed and dispensed epoxies and urethanes into DeSantis Mechatronics vacuum chambers for superior penetration.

Our Process

We Assess Your Needs

We listen. This is the first thing we do. We start by asking you questions about your formulations and process requirements. We do this on the phone, or if you prefer, we send you an interactive .pdf questionnaire. Your assistance and the information you provide to us at this stage, helps us to consider your needs, discuss your options and quickly respond back to you with complete system solutions.

We Decide on the Best Option Together

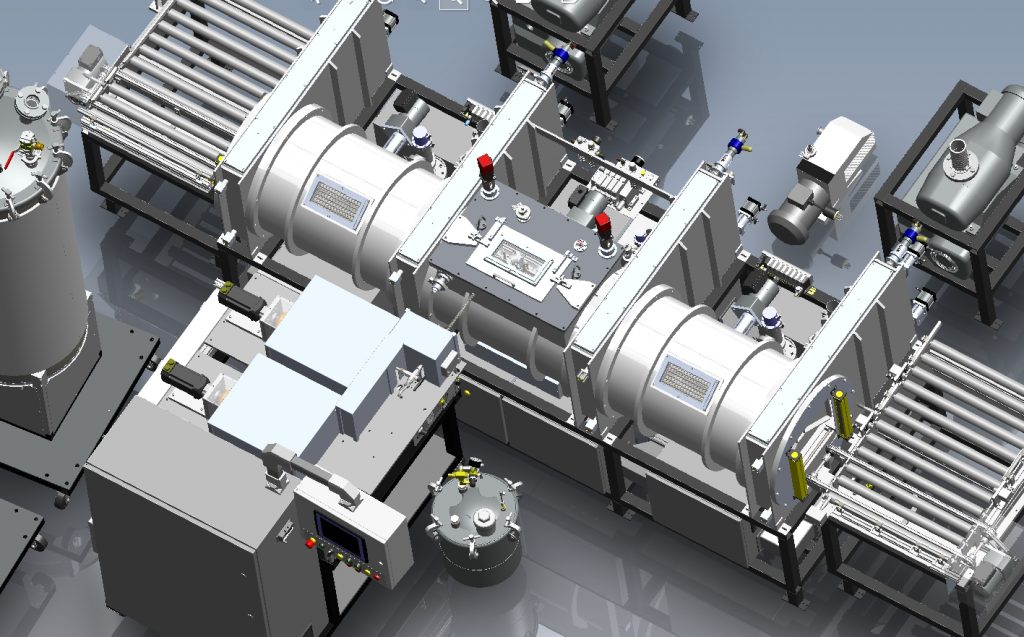

From our 45-years of experience, we have the ability to recommend, design and build a unique system with a combination of proven components. We often suggest and build new features into our systems; features that help your process run better. If you want us to add something special to your system, just ask. All of our systems are designed using state-of-the-art SolidWorks 3D product modeling software. 3D modeling allows us to easily add or remove system features while we select the system design that works best for you.

We Execute

To insure fast system start-up, our trained engineering, manufacturing and technical staff is available to assist you through every step of system design, system fabrication and operator training. After delivery we can visit your plant to check the installation and assist you with running your new system with your resin materials. Your designated machine-operators can be trained on proper system start-up and system operation, as well as hands-on maintenance instruction.

DeSantis Mechatronics takes the guesswork out of multi-component and single-component resin dispensing. We offer you a comprehensive range of standard and custom multi-component systems, plus, options and accessories to match your specific formulation and process requirements. We are committed to responsive after-sale service and technical support, always available and just a phone call away.